When using mechanical equipment, we need to master some common sense. It can help us quickly solve mechanical equipment problems. The same is true for our paper cup machines. So, you have some common sense about paper cup machine troubleshooting. How much do you know? This article will tell you how to solve the problems of paper cup machines, and how to troubleshoot and maintain them.

Fault 1: Paper cup breaks

When the paper cup machine breaks out of paper cups during operation, first check whether the paper cup supply system is normal. If the paper is found to be jammed, it needs to be cleaned in time and ensure that other papers in the paper cup supply system are not affected. This can avoid the problem of paper cups breaking out again and ensure the normal operation of the machine.

Fault 2: Paper cup stuck

The jammed paper cup may be caused by the paper not being flat enough or puffy. In this case, you first need to stop the paper cup machine, then remove the paper cup and check the stuck position. If it is found that the paper is not flat enough or puffy, you need to replace the paper or adjust the paper supply system of the paper cup machine to ensure that the paper is flat and smoothly supplied, so as to avoid the paper cup from getting jammed again.

Fault 3: Paper cup machine does not rotate

When the paper cup machine does not rotate, there may be problems such as host circuit failure, drive motor failure, or transmission mechanism failure. Here are some troubleshooting steps:

● Check the power connection:

Make sure the power supply of the paper cup machine is properly connected and check whether the power supply is working properly.

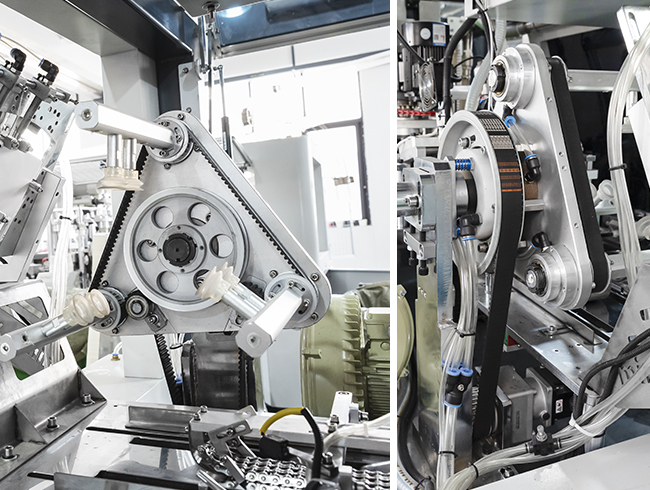

● Check the transmission mechanism:

Check the transmission mechanism of the paper cup machine, including gears, belts, etc., to ensure that they are not loose, broken, or damaged.

● Check the drive motor:

Check whether the motor driving the paper cup machine is running normally. You can tell by observing whether there is any sound or vibration from the motor. If the motor is not running, you may want to check the motor connections, switches, and the motor itself for damage.

● Check the host circuit:

If no problem is found in the above steps, there may be a fault in the host circuit. At this time, you need to check the host circuit board, fuses, and other components. If they are damaged or faulty, they need to be repaired or replaced.

Please note that the above steps are for reference only. For specific paper cup machine models and manufacturers, it is recommended to refer to its user manual or contact professional technicians for more accurate troubleshooting guidance.

Paper cup machine troubleshooting methods

● Chassis falls off

If the paper cup machine is used for a long time or is operated improperly, the chassis may fall off. If this happens, you need to place the machine on a flat ground, use a wrench to remove the screws, and then repair or replace the chassis. During maintenance, attention should be paid to maintaining a smooth connection between the chassis and the machine.

● The cutting knife is broken

When the paper cup machine is used for a long time or when cutting relatively thick paper cups, the cutting blade may become dull or worn, causing problems. At this time, the machine should be shut down and the cutting blade replaced. When replacing a new cutting knife, pay attention to the installation direction of the knife and the distance between it and the knife holder.

● Electronic component failure

When the paper cup machine is in use, electronic component failures may occur, such as mixing, circuit breakage, etc., which seriously affect the use of the machine. If an electronic component fails, it should be repaired or replaced under the guidance of professionals. Do not disassemble or assemble by yourself.

● Check the paper cup feeding system:

Check the paper cup feeding system to make sure they are not loose, broken, or damaged. Also, check whether the paper is flat and whether the paper supply is stable.

● Check the cup forming system:

Check the cup forming system to make sure they are not loose, broken, or damaged. Also, check whether the mold is clean and whether there are paper scraps or foreign objects stuck.

● Check the control system:

Check the control system of the paper cup machine, including PLC, touch screen, etc., to ensure that they are working properly. If there is a fault, you need to check the circuit board, fuses, and other components. If there is damage or failure, you need to repair or replace it.

Paper cup machine maintenance

(1) Regular cleaning:

Regular cleaning of the paper cup machine is very important. You can use a mild detergent and a soft cloth to clean the machine's exterior, control panel, and other parts. Make sure to disconnect the power when cleaning and avoid spraying water directly onto circuit boards or electrical components.

(2) Maintain transmission components:

Check transmission components such as gears and belts to make sure they are not loose, worn, or damaged. If there are any problems, replace them promptly.

(3) Lubricating components:

The transmission components of some paper cup machines require regular lubrication to ensure their normal operation. Refer to the owner's manual for proper lubrication methods and the type of lubricant to use.

(4) Update software:

If the paper cup machine has upgradeable control software, it is recommended to regularly check whether the latest version of the software is available and upgrade according to the guidance provided by the manufacturer.

(5) Check various sensors:

Paper cup machines are usually equipped with multiple sensors for monitoring and controlling operations. Regularly check the working status of these sensors to ensure they are functioning properly and are free of dirt or malfunctions.

(6) Train operators:

Ensure that operators are properly trained and understand the correct use and operating procedures of the paper cup machine. This will help reduce the risk of misuse and damage.

(7) Regular inspection and maintenance:

Regularly inspect various components of the paper cup machine, including the electrical system, hydraulic system (if any), and other key components. If any problems are found, repair or replace them promptly.

The paper cup machine must be well maintained when not in use to prevent the machine from becoming less efficient.