High Speed Single Plate Open Cam Paper Cup Machine

Specs PDF

Specs PDF

Specs PDF

Specs PDF

Through this video, we will show you the paper cup manufacturing processand superior performance of OCM12. This machine can produce cupsranging from 2 to 16 ounces, meeting various size requirements.

More videosOCM12 high speed paper cup machine can do 1.5-16OZ size, speed can reach 80-100PCS/MIN. The oil lubrication system can make the machine run more smoothly and extend the life of the machine.

12 sensors can protect the operation of the machine, and in the case of machine failure, timely alarm and stop. The control panel is used to display the machine data and set the machine data more accurately.

Safety cover and backing paper cutting device can make the machine shell more firm and achieve the purpose of preventing backing paper clogging.

The use of stepping motor and servo motor can more accurately feed the backing paper to avoid waste.

Intelligent model high-speed paper cup machine MYC-OCM12 with vacuum suction unit to suck down and feeding paper fan, sensor failure detecting and it can send the alarm automatically if the machine has any problem.

| Model | High Speed Single Plate Open Cam Paper Cup Machine MYC-OCM12 |

| Paper Cup Size | 1.5 -16 0Z (Mould exchangeable, Max Cup Height: 136mm , Max Bottom width :85mm |

| Rated Speed | 80-100pcs/min ( Speed affected by cup size, paper quality & thickness)9OZ, 280GSM paper cup Stable running speed 80 pcs each min. |

| Raw Material | One or Two side PE coated Paper(Popular for Hot and Cold drink Cups) |

| Suitable paper weight | 140-350gsm |

| Power Source: | 50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power requirement |

| Total Power | 8.5 KW |

| Total Weight | GW/NW:1900KGS/1750KGS |

| Pack Size(LWH) | 2270*1400*1970mm 1000*750*2100mm |

| Working Air Source | Air pressure:0.4Mpa:

Air Out-put:0.6m³/minute |

| Cup Side Welding | Ultrasonic heater |

| Cup Bottom Heating | 1side PE paper by heater knurling:

2side PE paper by cool device (circle water) knurling |

| Cup Bottom Knurling | Heater Knurling (if use single PE coated paper) |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

|

|

|

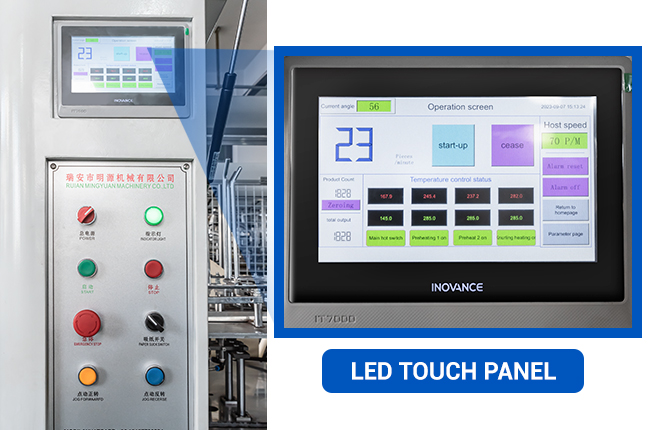

Control Panel lt adopts PLC controller and touch screen (man -machine interface)all the working parameters can be setup on the control panelwhich is convenient for parameter setting and adjusting.(easy operate) |

|

|

|

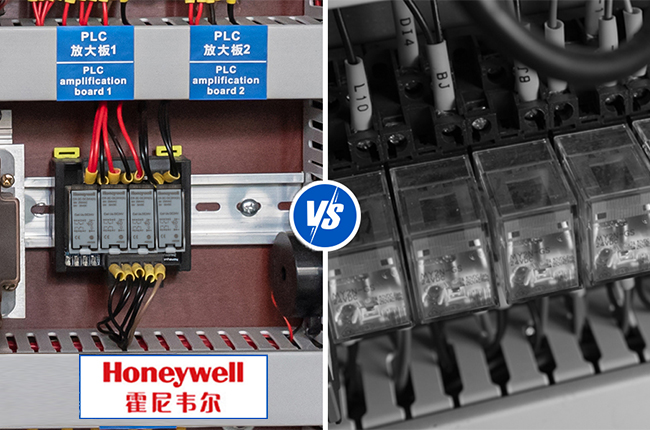

honeywell relay Best lmported US brand relay, best qualityand longer service life |

Other China brand relay easy broken |

|

|

|

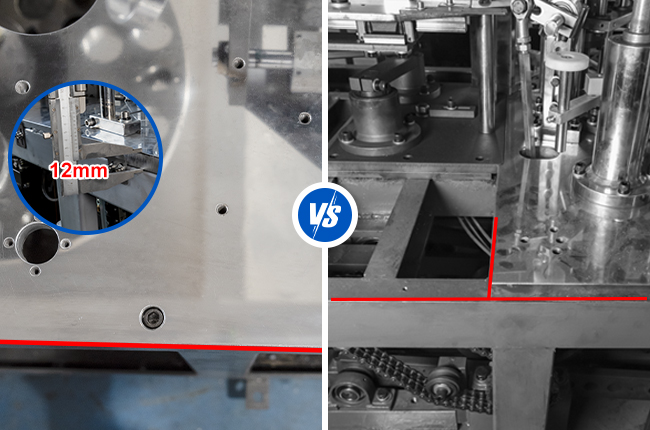

Cover Platen Board Longer service lifeMore stable and better. |

Other Thinner board and it is easyget rusted and broken |

|

|

|

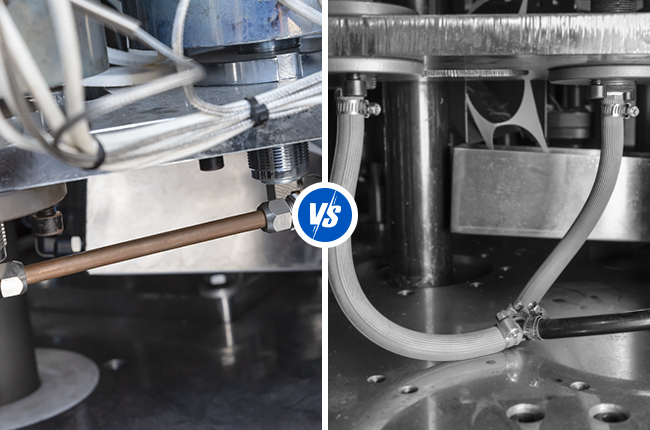

Metal pipes lt is for the connection of hot air blowing heater , durable and high temperature resistance. |

Other plastic pipe is broken easily,and cause air leaking and cup bottom leakage issues. |

|

|

|

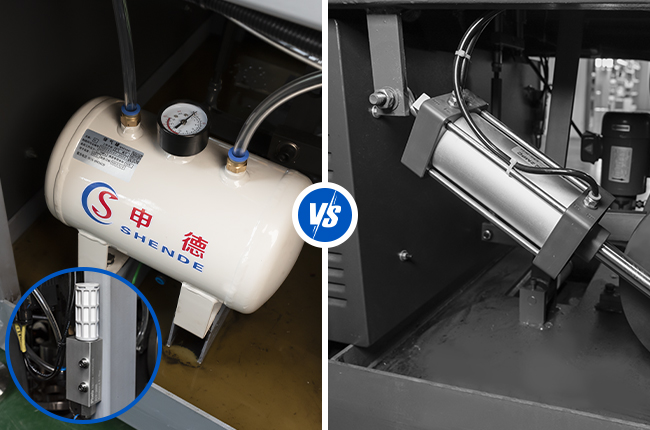

Air filter Dryer tank Prevent wet air with water from entering solenoid valve, longer service life, more stable and better. |

Other Paper suction is controlled by air cylinder, long timerunning will make the air sealing ring very hot and be broken easily and cause air leaking is sue. |

|

|

|

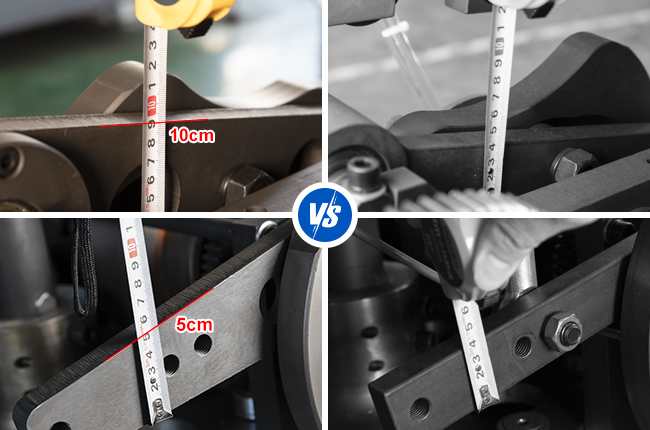

Metal rod accessories thickness upgrade New design is durable better quality is not easy to be broken in long time running. |

Other The rod will be break easily in short time running. |

|

|

|

Mould with air hole lt can cool the mould easily and make the cup discharge easily . |

Other The cup will be sticked to the mould and cause issues |

|

|

|

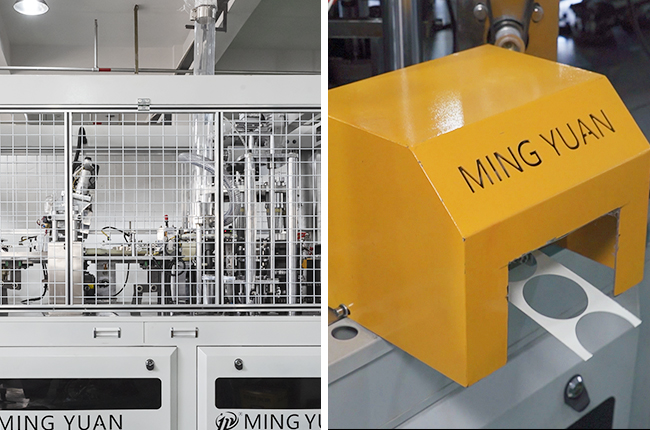

Safety Cover Protection during the operation of the machine. |

Bottom Waste Paper Cutting Unit Cut the waste paper into pieces , and less paper stuck issues |