Intelligent Model High Speed Printing Machine

Specs PDF

Specs PDF

Specs PDF

Specs PDF

Through this video, we will demonstrate the printing machine PM850. This machine is specifically designed for efficient printing processes, ensuring superior performance. It can accurately print various materials, meeting different printing requirements.

More videos| Model | Intelligent Model High Speed Printing MAchine MYC-PM850 |

| Printing Speed | 60-100m/min |

| Printing Color Number | 1-6 colors |

| Maximum PrintingWidth | 850mm |

| Maximum Feeding Width | 860mm |

| Maximum Unwinding Rewind Diameter | 1300mm |

| Maximum Printing Size | 180-380mm |

| Registration Accuracy | ±0.15mm |

| Voltage | 380V±10% |

| Total Power | 25kw |

| Air Source | 0.6MP |

| Oillubrication | By manual |

| Weight | 4500kg |

| Dimensions | 3500X2100X2350mm |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

|

|

|

Control Panel Control panel with good quality switches,tempreture controller,dis-tributor controller and pressing roller controller.And all the operation of machine can be easily finished by this panel |

|

|

|

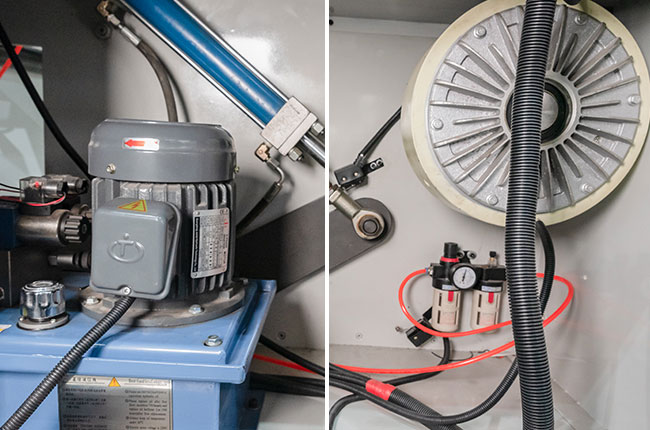

Hydralic and MagneticParticle Controller System Hydraulic system is for loading&unloading the raw materials.The Magnetic Particle Controller Systemis used to control unwindingrewinding tension system, it can also be used for buffer start, overload protection, speed requlation |

|

|

|

Motor It is used better quality variable fre-quency stepless motor in machinefor speed regulation .( longer ser-vice life) |

|

|

|

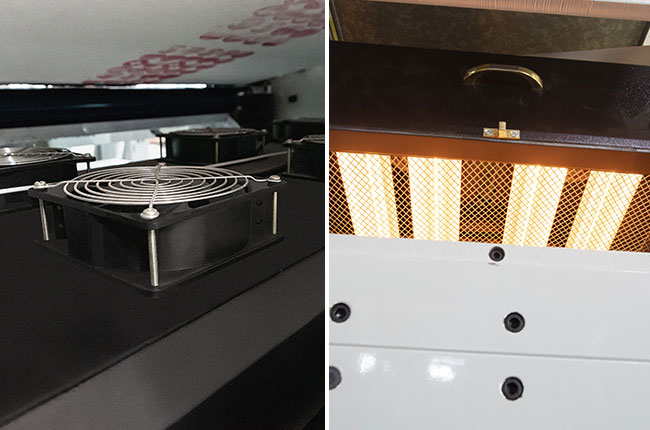

IR Drying Unit The machine is equipped withdrying fans and each Printing Unitcomes with 1 Unit Infrared HeatingDrying Oven to make the ink dryfaster. |

|

|

|

Still View Camera(Optional) Enlarge and inspect print images running at highspeeds for timely defect detection and improvedprint quality |

|

|

|

Print DigitalPlate Using the rubber membrane which can be changedeasily for different printing logo design. Each printingunit can be driven and released independently andcontinue printing |